Pre Treatment

Before the etching process, inspect and clean the Invar raw material.

Due to the characteristics of the Invar material, the metal mask of the finished product, such as sagging, is deformed over time.

Sewoo Incorporation predicts errors and deformation after the etching process and finished products and reflects them in the product design to derive the optimal product condition.

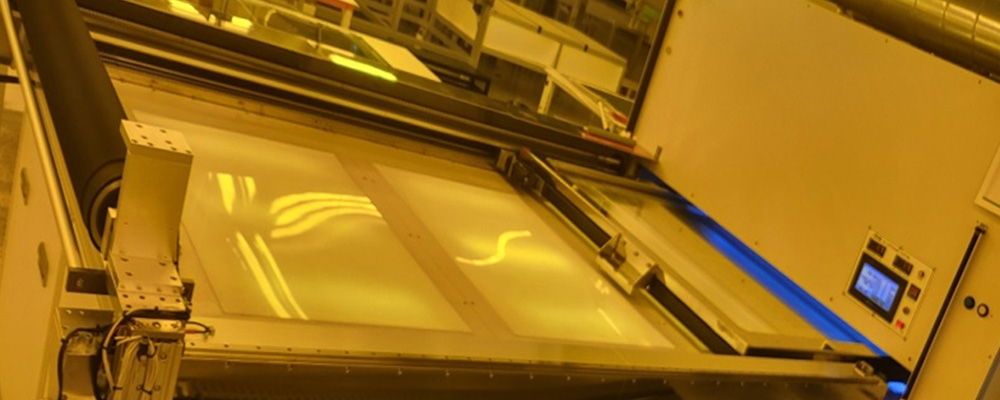

Laminating

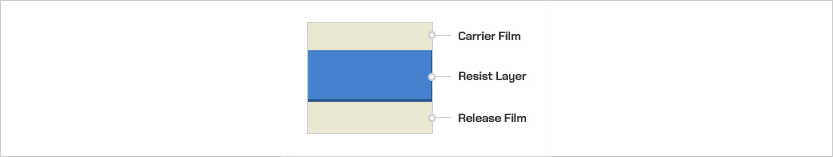

For pattern etching, the film is laminated on the Invar raw material.

The Invar is coated with film to protect the product from scratches and to allow etching patterns to be formed during the etching process.

Sewoo Incorporation manufactures OLED masks with the highest performance in Korea and abroad by using

the high resolution of the photolithography process and high-adhesion DFR film.

High adhesion

Sillicone Free

High resolution

Carrier film at room temperature

Visibility

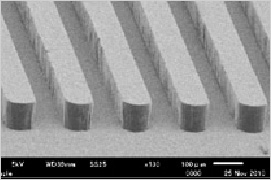

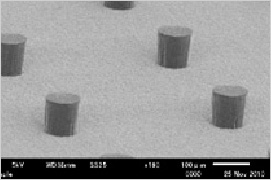

MS7100 L/S=100/100μm

MS7100 80μmΦD o t

Film Photo Mask

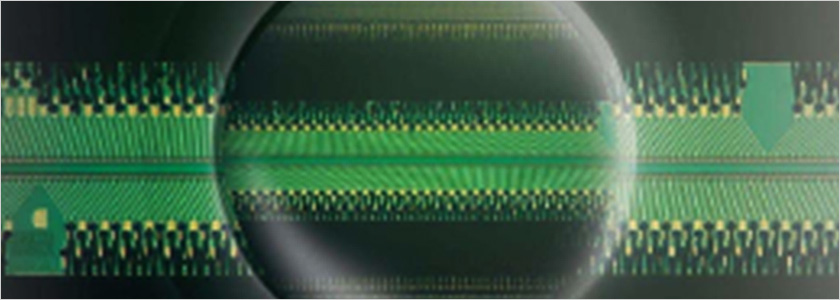

The mask film for OLED mask/split stick required for UV exposure process is combined with the output and Invar material.

Using a photo plotter with beam equalization, based on the recording signals of various pattern parts designed with CAD/CAM,

the high-power semiconductor laser is used as a photofilm to expose to the surface.

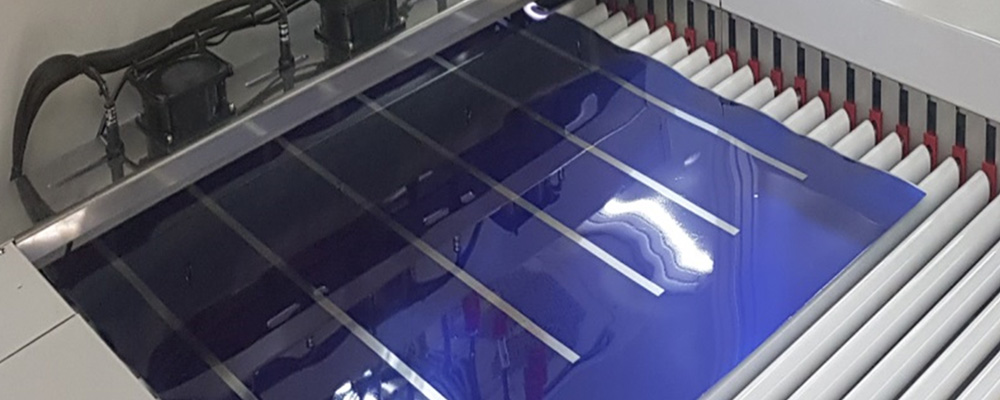

Exposure

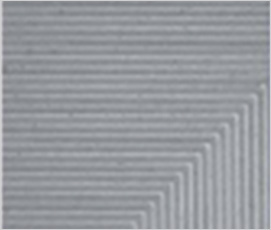

Proceed with the exposure process to expose the product to light according to the designed etching pattern.

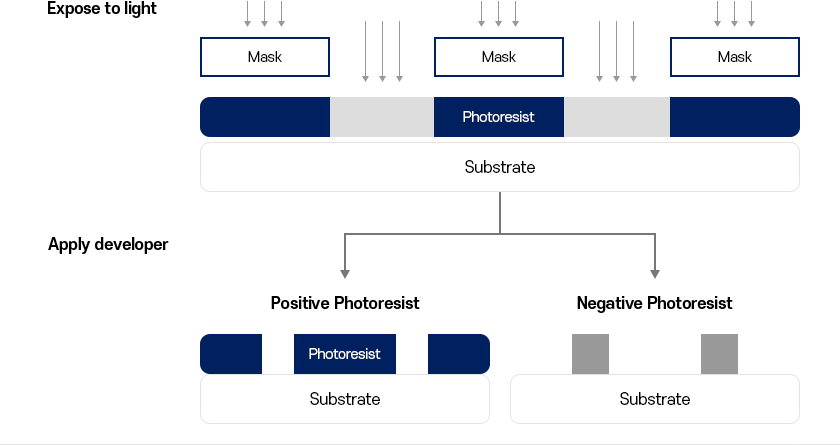

Delete the light-exposed area in the subsequent etching process or leave the exposed area and delete the other areas.

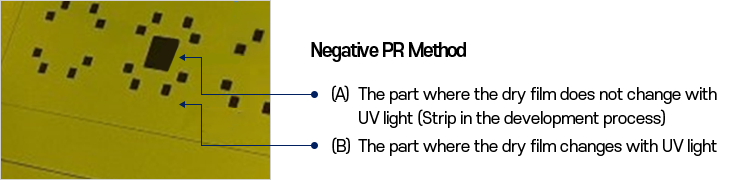

There are Positive PR (Photolithography) that deletes the light-exposed area, and Negative PR that leaves the light-exposed area and deletes the other area. Currently, Sewoo uses the Negative PR (Photolithography)

When processing the pattern, the dry film is changed with UV light (part B), so that the film is not peeled off in the developing process,

and part A where UV light is not transmitted is peeled off in the developing process and etched in the etching process.

Mask

Plate manufactured to form the necessary fine patterns

Photo Resist(PR)

There are two types of materials whose properties(solubility) are changed by light of a specific wavelength, Positive PR and negative PR.

Positive PR : The part that is illuminated is removed by the developer

Negative PR : The part that is illuminated is not removed by the developer

Development

When the PR material applied to the product surface is lighted and the area that has received light and is not,

the undesired part is selectively removed through the developer to realize patterns, shapes, etc.

Etching

Extract along the PR remaining on the surface of the deposition layer.

There are two methods of etching. The first one is wet etching, which causes a chemical reaction on the surface to be etched, and the other one is dry etching, which proceeds without a chemical solution using a physical method.

Strip

The process of removing PR from the product that has completed the etching process is carried out.

Cleaning

The cleaning process is carried out to cleanly remove the solution used for laminating, PR, and etching.

Sewoo Incorporation independently developed cleaning solution and cleaning equipment and allows you to clean in the best condition without any damage remaining in the mask.